The boss of mosaic coat racks

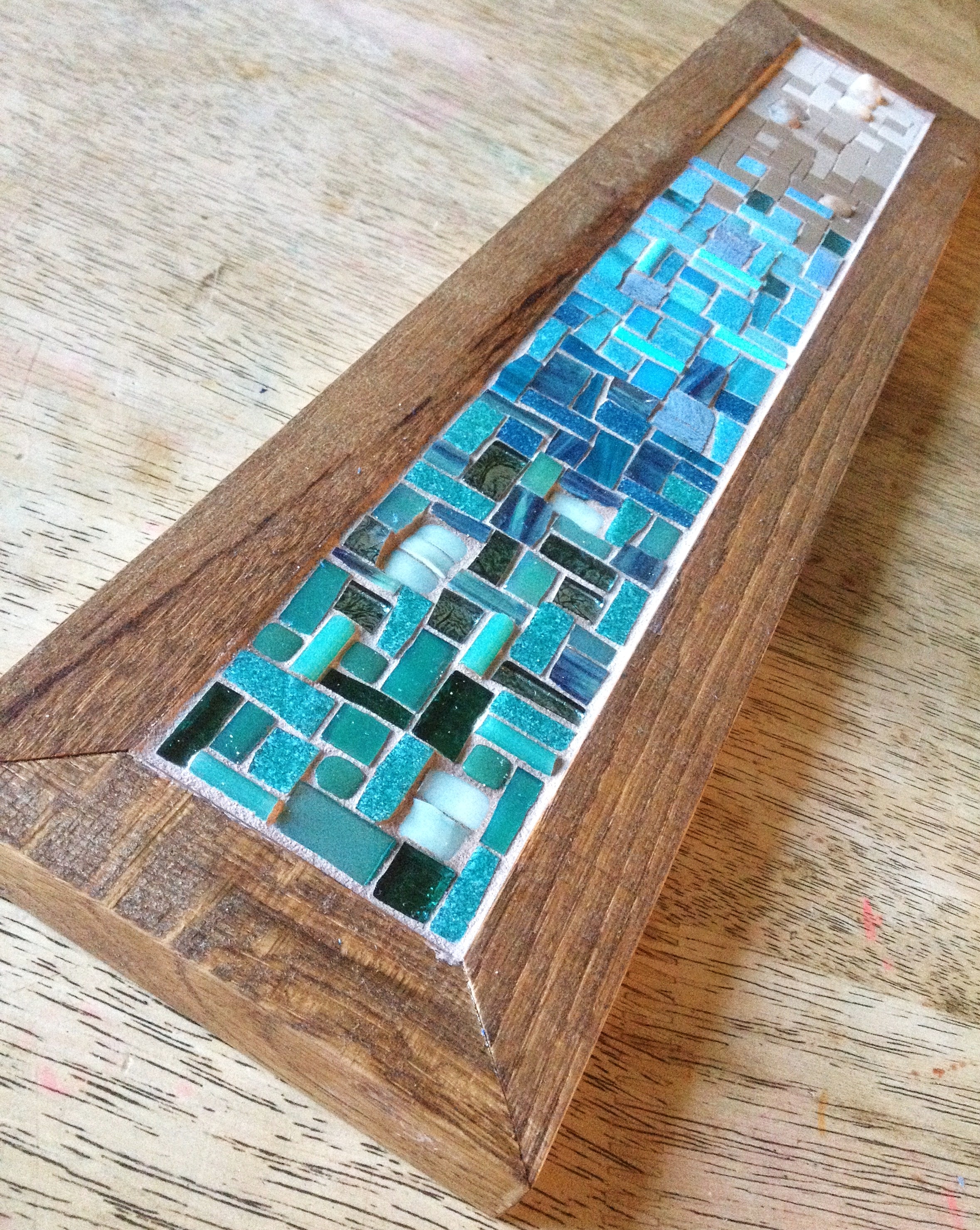

We recently finished a commissioned coat rack based on our line of mosaic coat racks in reclaimed wood frames with hand-forged hooks. This big guy, however, was almost four times as big as our usual coat racks!

The client's hallway rug was the source of inspiration for both the colors and the design.

Pulling together the color palette and sketching out design ideas.

Johannah used grout lines and andamento, the visual flow created by the placement of the tesserae (tiles), to create a sense of movement and balance of colors similar to the rug.

Kyle created a reclaimed wood frame twice as wide as our usual frames to support both the physical and visual weight of the mosaic. He added his V-style hand-forged hooks to complete the piece.

You might also like

custom coat rack, mosaic coat rack, entryway hooks

Custom coat racks in shades of blue

custom coat rack, mosaic coat rack, entryway hooks

custom coat rack, mosaic coat rack, entryway hooks

blacksmith, exterior design, interior design, gifts, mosaic, mosaic address, custom art, address, mosaic inlay, custom furniture, modern metal furniture, custom metal furniture, mosaic wall art, mosaic coat rack, mosaic address plaque, entryway bench, hall bench, hand forged furniture, custom bench, custom coat rack, steel and wood furniture, entryway hooks

blacksmith, exterior design, interior design, gifts, mosaic, mosaic address, custom art, address, mosaic inlay, custom furniture, modern metal furniture, custom metal furniture, mosaic wall art, mosaic coat rack, mosaic address plaque, entryway bench, hall bench, hand forged furniture, custom bench, custom coat rack, steel and wood furniture, entryway hooks

blacksmith, exterior design, interior design, gifts, mosaic, mosaic address, custom art, address, mosaic inlay, custom furniture, modern metal furniture, custom metal furniture, mosaic wall art, mosaic coat rack, mosaic address plaque, entryway bench, hall bench, hand forged furniture, custom bench, custom coat rack, steel and wood furniture, entryway hooks